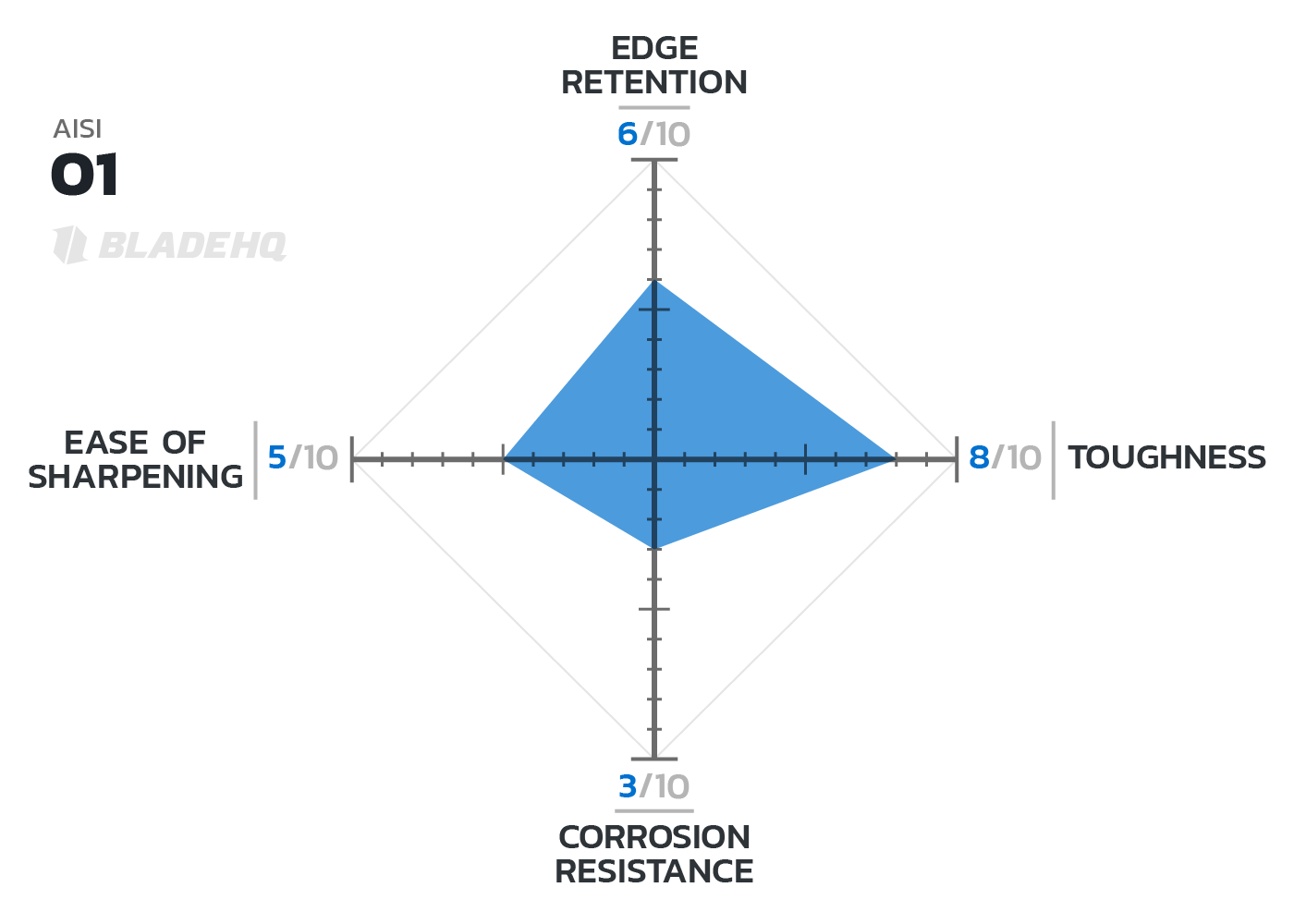

Heat treat blade geometry the job at hand and the sharpening of the blade all play a massive role in the performance of the steel. They seem to have done an excellent job turning this ultra hard but very brittle material into an extremely tough and durable blade with the use of special heat treatments and very high carbon contents.

Stop Buying Knives Because They Look Cool It S All About

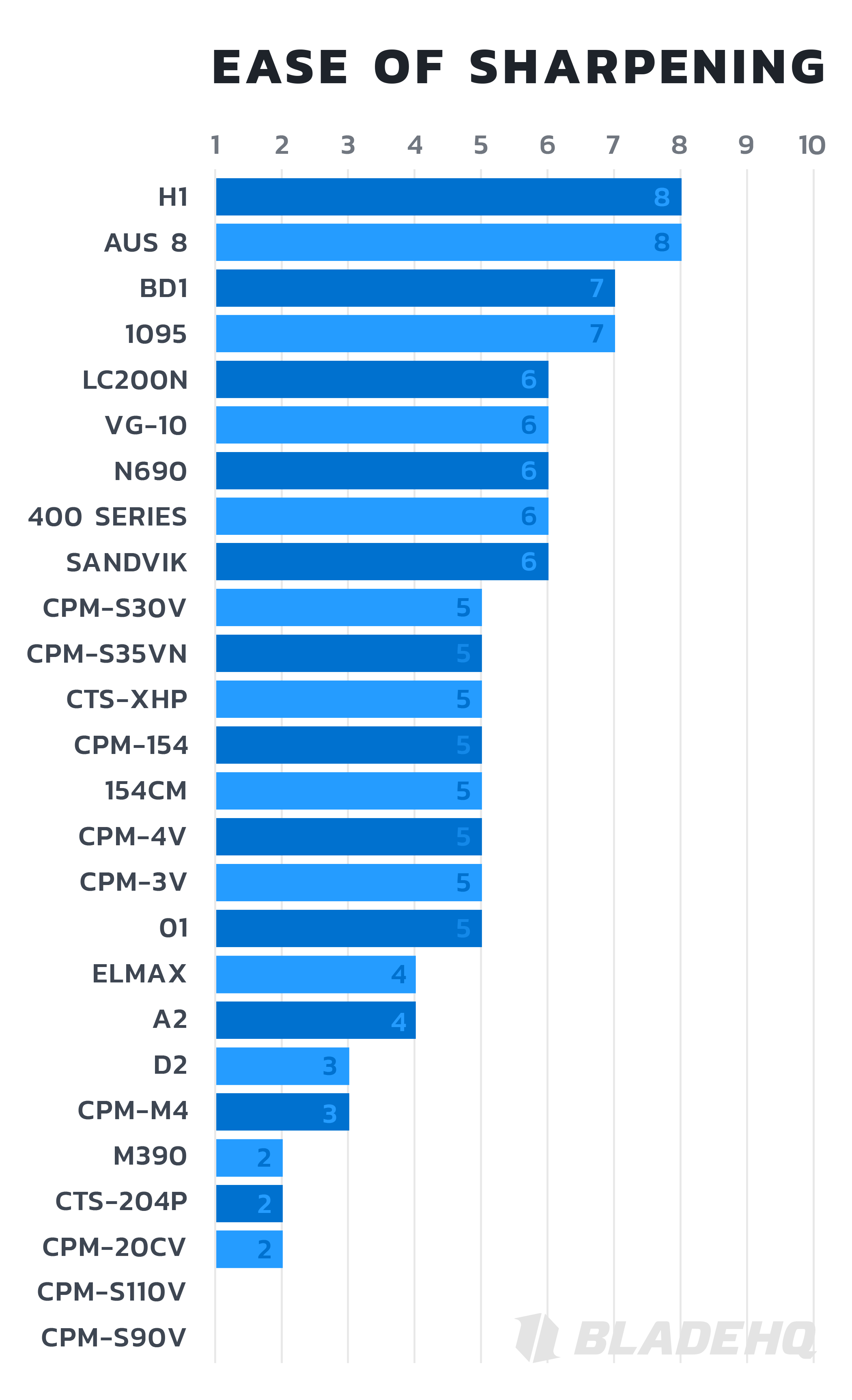

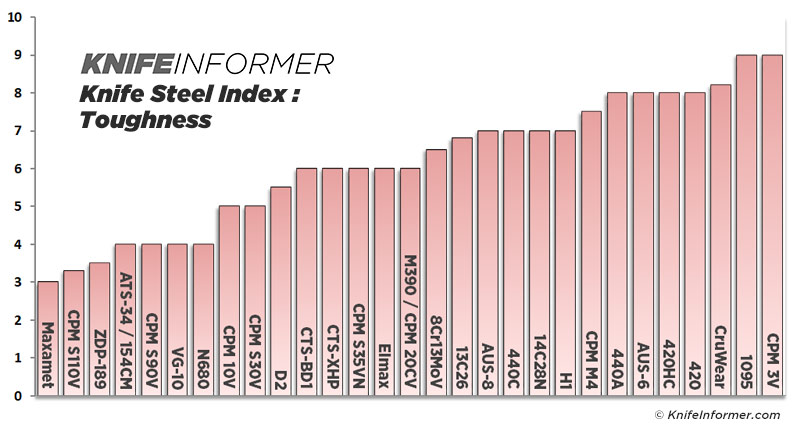

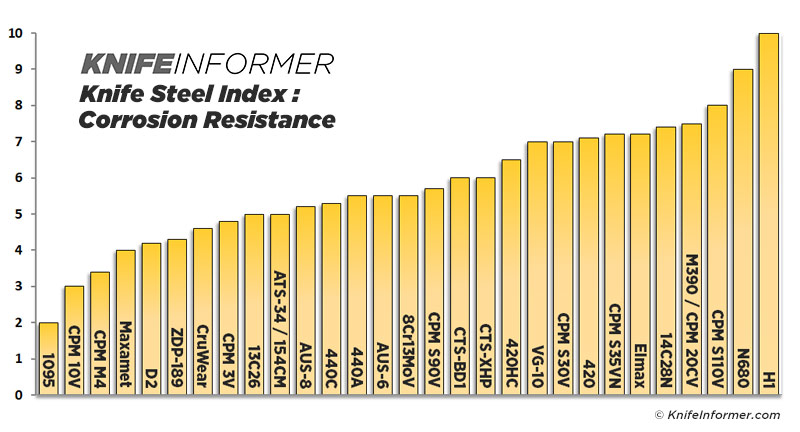

Knife steel tier list. Alongside edge geometry and design blade steel is a critical element that determines how a knife performs. Blade steel is totally a super important factor to consider when buying a knife but wait a secondit isnt the be all end all. Steel is essentially an alloy ie. 1095 blades also tend to be thicker because a thin knife made of hard 1095 can be too brittle. Twisted sisal merch thanks to misheardknifereviews. In choosing the best pocket knife you should pay particular attention to the type of steel used in the blade.

1095 is a non stainless carbon steel with approximately 095 carbon in the bladethis makes for a tough knife that holds an excellent edge but its prone to rusting if you dont take care of it. Frequent lubrication and proper storage will keep things in good order. So heres my attempt with a basic overview of steel as a whole a decent non exhaustive list of all the steels i consider to be relevant in the knife community by todays standards and an outline of each steels place in the market. These metals arent used as much as many of the others on this list but one brand that we really enjoy at marine approved in the medium tier level of knives is crkt. A mix of carbon and iron that is often enriched with other elements to improve certain characteristics depending on the desired application. This made me feel that a truly comprehensive guide on the topic of blade steels was warranted.